Vapor Blasting

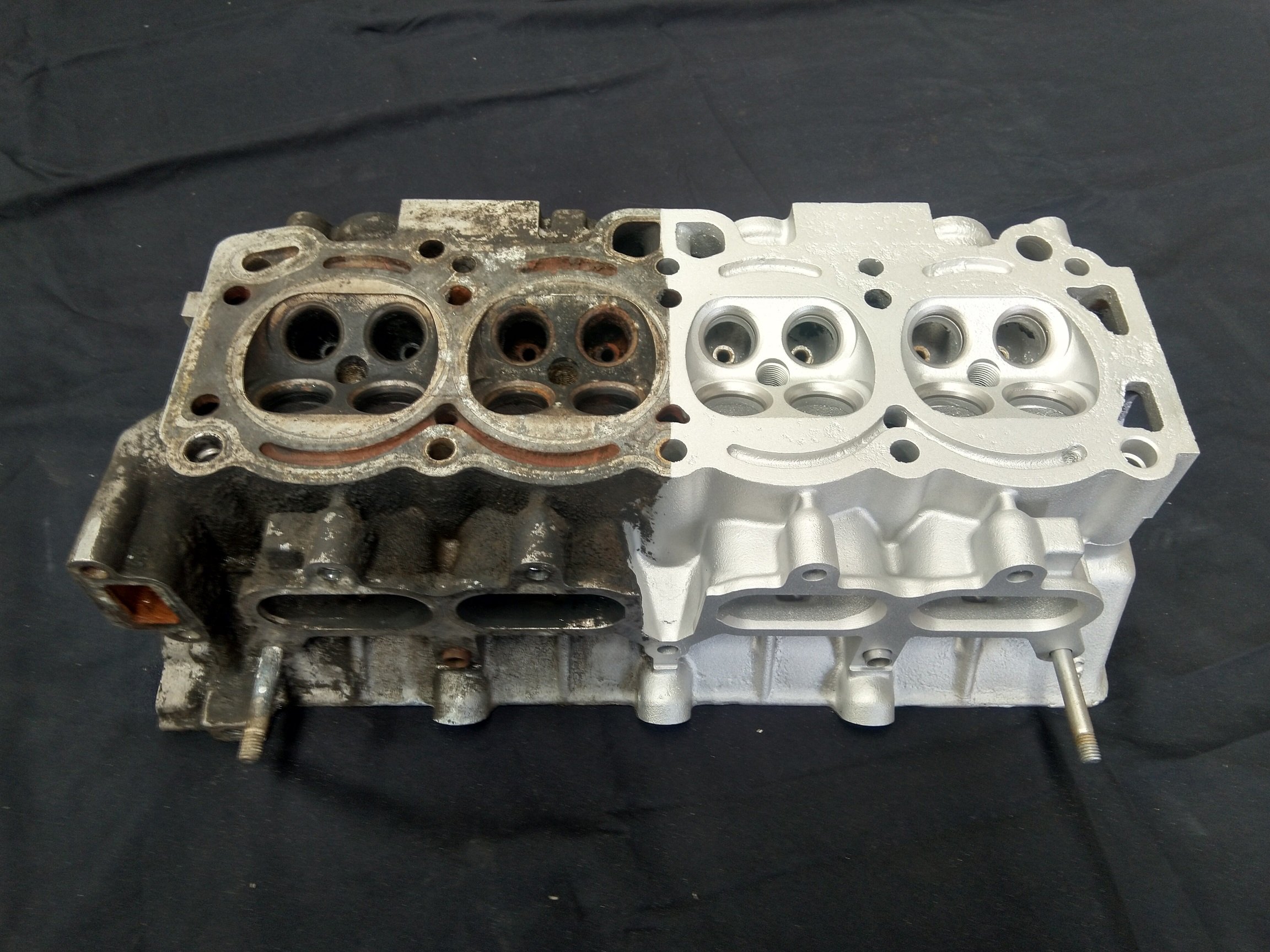

Vapor blasting is a cleaning and surface finishing process that uses a combination of water, abrasive media (such as ceramic beads or glass beads), and compressed air to clean and smooth surfaces. This process is often used for delicate parts that require a more gentle touch compared to traditional sandblasting or abrasive blasting.

The key to vapor blasting is the use of water as a medium, which helps to reduce heat buildup and prevents the abrasive from being too harsh on the surface. The result is a smoother, polished finish without the roughness or damage that might be caused by dry abrasive methods.

Vapor blasting is commonly used in industries like automotive (for engine parts, for example), aerospace, and restoration, especially when dealing with aluminum, steel, or other soft metals. It can clean, deburr, and even improve the surface's appearance by providing a satin-like finish.

Pricing is $1.67 Per Minute. With a 1/2 Hour Minimum.